Angle Grinder Discs & Accessories

Angle grinder discs are essential for cutting, grinding and finishing work on site. At ITS, we stock discs for metal, masonry, tile and more – including cutting wheels, flap discs and diamond blades from trusted trade brands.

Types of Grinder Discs We Stock

Whether you’re slicing through steel or polishing up edges, you’ll find what you need here:

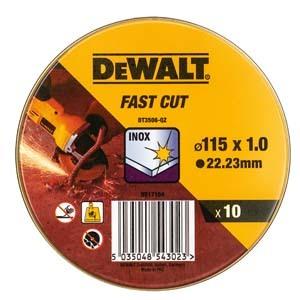

- Cutting Discs – Thin-profile discs for fast, clean cuts in metal, rebar, bolts and pipework.

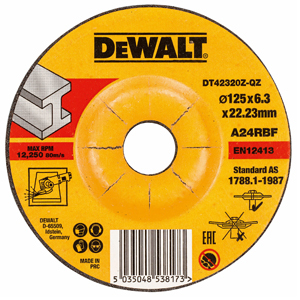

- Grinding Discs – Thicker and tougher, designed to remove material or reshape welds.

- Flap Discs – Sanding and finishing discs with layered abrasive flaps for smoothing metal or wood.

- Diamond Discs – For stone, concrete and masonry. Long-lasting and suitable for wet or dry use.

Grinder Discs Are Perfect For:

- Cutting metal conduit, rods and sheet steel

- Smoothing welds and surface prep in fabrication

- Grinding back concrete edges or slabs

- Tile and paving slab cuts using diamond wheels

- Shaping and sanding with flap wheels

Choosing the Right Disc

Not all discs suit all jobs – or all grinders. Here’s how to pick the right one:

1. Disc Size

Most grinders use 115mm or 125mm discs. Bigger grinders can take 230mm – always check guard size and RPM rating.

2. Material Type

Use metal-cutting discs for steel, and diamond or stone-rated discs for masonry and concrete.

3. Task Fit

Cutting discs are thin for fast results. Grinding wheels are thicker and remove more. Flap discs finish or blend. Match the disc to your end goal.

Grinder Accessory Brands We Trust

We only stock trade-grade discs from trusted suppliers:

1. Bosch & Makita

Reliable cutting and grinding discs for site use, with safety specs and long life.

2. DeWalt & Rubi

High-performance abrasive and diamond solutions for fast cuts and smooth finishes.

3. Vaunt & Ox Tools

Great-value multipacks and specialist discs ideal for metalworkers and fit-out teams.

Grinder Disc FAQs

Can I use a cutting disc for grinding?

No – cutting discs are too thin and may shatter under side pressure. Always use a grinding disc for shaping or smoothing.

What’s the difference between flap discs and grinding wheels?

Flap discs use sandpaper-like flaps to smooth surfaces, ideal for finishing. Grinding wheels are coarser and designed for bulk removal or weld clean-up.

Are diamond discs suitable for dry cutting?

Yes – many diamond discs are rated for dry cutting. Using water helps reduce dust and prolong disc life but isn’t always required.

What RPM rating should my disc have?

Match the disc RPM to your grinder’s max speed. Most 115mm discs are rated for up to 13,300 RPM.

Can one disc be used for all materials?

Not safely – always choose the right disc type and abrasive for your material. Misuse may cause poor results or disc failure.