Circular Saws

Circular saws are versatile cutting tools, essential for woodworking, metalworking, and construction tasks. Built for speed and power, they make straight cuts in wood, metal, and plastic with ease, making them ideal for professionals and DIY enthusiasts alike.

Who Uses Circular Saws?

Circular saws are a go-to tool for professionals across various trades. Their versatility and power make them suitable for different materials and tasks, offering clean and efficient cuts every time.

- Carpenters – Carpenters rely on circular saws for making fast, straight cuts in wood, essential for framing, decking, and custom woodworking projects.

- Metalworkers – Metalworkers use specialized blades with circular saws to cut metal sheets and pipes with precision and speed, ideal for structural and custom metalwork.

- Contractors – Contractors use circular saws on construction sites to cut lumber, plywood, and other materials for framing and general construction tasks.

- DIY Enthusiasts – Homeowners and DIYers use circular saws for various projects, such as building furniture, shelves, or cutting down lumber for garden or household improvements.

Circular Saws Are Great for Jobs Such As:

- Building furniture – Use circular saws to cut wood or plywood precisely, making it easy to construct tables, cabinets, and shelving units.

- Framing and decking – Ideal for carpenters and contractors, circular saws provide fast cuts for framing lumber, deck boards, and other outdoor structures.

- Metalwork – With a metal-cutting blade, circular saws can slice through metal sheets, rods, and pipes, making them versatile for custom metal fabrication.

- Creating straight cuts in plywood – Perfect for sheet goods, circular saws allow quick, straight cuts, useful in cabinetry and paneling.

- DIY Home Projects – From garden fencing to home repairs, circular saws help DIYers tackle a wide range of cutting tasks with efficiency.

How to Choose the Best Circular Saw

Selecting the right circular saw can enhance your project efficiency and accuracy. Key factors like power source, blade size, and speed control help you choose a tool that suits your specific needs. Here are the most important specifications to consider:

1. Power Source Options

Corded Circular Saws: Great for continuous use on heavy-duty tasks. These provide consistent power without the need for recharging, though mobility is limited by the cord.

Cordless Circular Saws: Perfect for on-the-go work. Advances in battery technology offer powerful cuts, though battery life may require monitoring on larger projects.

2. Blade Size and Compatibility

Circular saws typically come with blade sizes ranging from 6.5 to 7.25 inches. A larger blade size allows for deeper cuts, ideal for thicker materials. Verify blade compatibility to ensure optimal performance.

3. Adjustable Speed Control

Variable speed settings let you tailor the saw's speed to the material, providing better control and finish quality. Higher speeds are great for quick cuts, while slower speeds suit detailed or intricate work.

4. Bevel Capacity and Adjustability

A saw with a bevel feature allows angled cuts. Look for a circular saw with adjustable bevel settings, typically between 0° and 45°, to expand cutting options for framing and carpentry projects.

5. Safety Features

Safety should be a top consideration. Look for circular saws with features like electric brakes, which stop the blade quickly, and blade guards, which reduce the risk of accidental contact.

6. Ergonomics and Weight

If you’ll be using the saw for extended periods, prioritize models with ergonomic handles and lightweight construction to reduce fatigue and improve maneuverability.

Popular Accessories for Circular Saws

Using the right accessories with your circular saw can enhance cutting accuracy, improve safety, and streamline your workflow. Here are some of the top accessories that make circular saws even more versatile and effective.

1. Circular Saw Blades

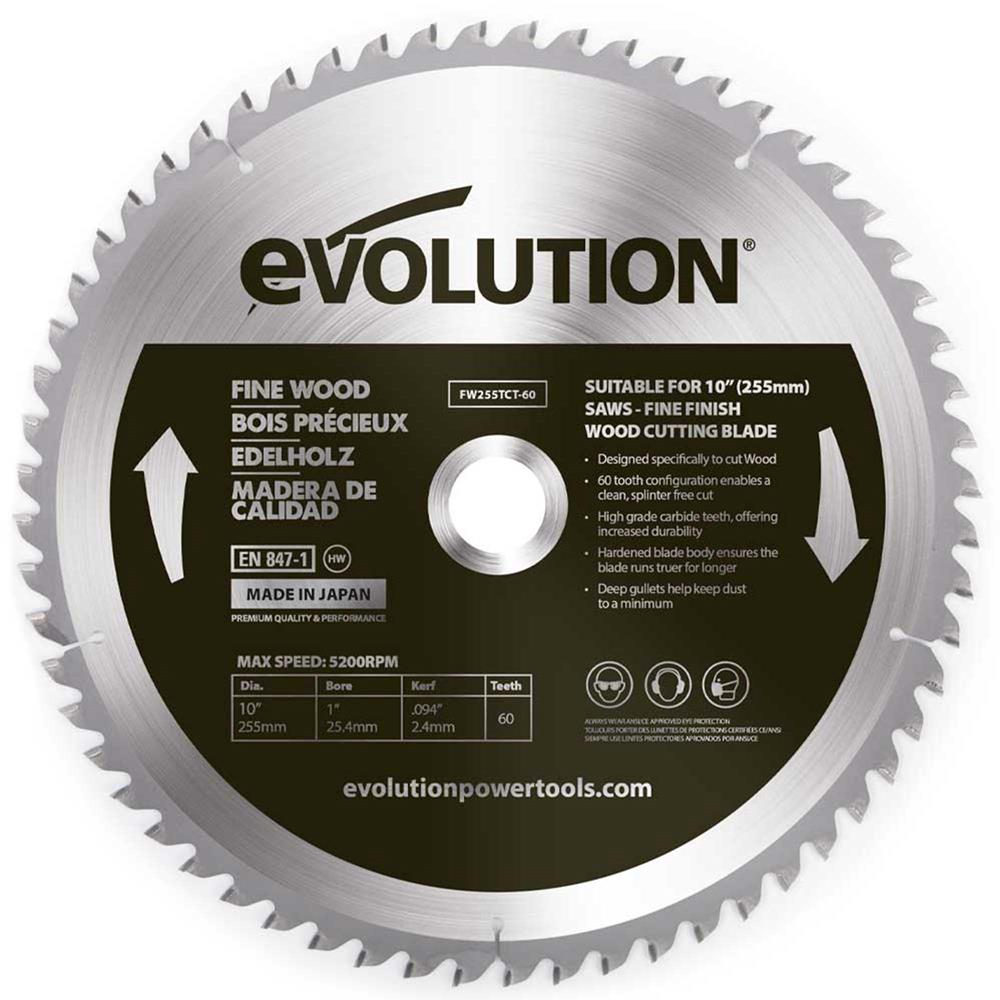

Switching blades can tailor your saw to specific materials. For instance, a fine-tooth blade is ideal for wood, while diamond blades work best for cutting masonry. High-quality blades also ensure cleaner, faster cuts.

2. Guide Rails

Guide rails help achieve precise, straight cuts every time. They’re especially useful for long cuts on sheet materials, providing better control and reducing the risk of veering off track.

3. Dust Extraction Adapter

A dust extraction adapter connects to a vacuum system, keeping your workspace clean and reducing airborne dust. This accessory is crucial for indoor projects and helps maintain visibility of the cutting line.

What Types of Blades Can Circular Saws Use?

Circular saw blades come in a variety of sizes, typically ranging from 216mm to 350mm, allowing you to choose the correct size for your saw. Kerf refers to the width of the cut the blade makes; thinner kerfs require less power and are ideal for finer finishes, while wider kerfs are more robust, designed for faster, heavier cuts in tough materials.

| Blade Type | Primary Application | Example Image |

|---|---|---|

| Carbide-Tipped Blade | Ideal for smooth, precise cuts in wood and plywood |  |

| Metal-Cutting Blade | Best for cutting through steel, aluminium, and other metals |  |

| Masonry Blade | Perfect for cutting concrete, brick, and other hard materials |  |

| Fine-Finish Blade | Used for fine cuts on furniture-grade wood or trim |  |

Frequently Asked Questions

What is the difference between a circular saw and a miter saw?

A circular saw is a versatile tool for straight cuts in various materials, while a miter saw is specifically designed for angled cuts and is often used for precise woodworking tasks. If you need portability and flexibility, a circular saw is ideal.

Can a circular saw cut through metal?

Yes, with the right blade. Metal-cutting blades can be fitted on circular saws for light to medium-duty metal cuts. However, for frequent or heavy-duty metalwork, a dedicated metal-cutting saw is recommended for safety and efficiency.

How deep can a circular saw cut?

The depth of cut depends on the saw and blade size. A 7-1/4" circular saw, the most common size, can typically cut up to 2-1/2 inches deep at 90 degrees. Adjustable settings allow for shallower cuts to suit different project needs.

How do I maintain my circular saw blade?

To extend blade life, clean it regularly to remove resin and debris, avoid cutting nails or other hard materials, and replace it if it becomes dull. A sharp blade ensures cleaner cuts and reduces strain on the motor.

Are corded or cordless circular saws better?

Corded circular saws offer continuous power and are generally more affordable, making them suitable for prolonged tasks. Cordless saws provide portability and convenience but require charged batteries, which may limit runtime on larger jobs.