Mitre Saws

Mitre saws make angled cuts with speed and accuracy, essential for tradespeople and DIY enthusiasts tackling precise woodwork, trims, and mouldings. With easy adjustability and powerful performance, mitre saws provide reliable, clean cuts for every project.

Who Uses Mitre Saws?

Mitre saws are trusted by professionals and hobbyists alike, offering the flexibility needed for everything from crafting fine furniture to framing walls. Here’s a closer look at who benefits from this versatile tool:

- Carpenters – Rely on mitre saws for custom cuts on wood trim, framing, and moulding, enabling clean, precise angles every time.

- Joiners – Use mitre saws for creating fitted pieces in cabinets and custom furniture, ensuring tight, professional joins.

- Builders – Employ mitre saws on-site for framing and fitting structural components, from skirting boards to door frames.

- DIY Enthusiasts – Home users turn to mitre saws for tasks like cutting boards, fitting trims, and creating unique woodworking projects.

Mitre Saws Are Great for Jobs Such As:

- Fitting skirting boards – Achieve seamless joins and perfect angles for smooth, professional edges on skirting boards.

- Cutting crown moulding – Make compound cuts effortlessly to fit corners and crown moulding for interior trim work.

- Building picture frames – Mitre saws allow for sharp, precise angled cuts to create custom frames and decorative woodwork.

- Decking installation – Speed up decking projects by making accurate crosscuts and mitre cuts on timber beams and boards.

- Custom furniture projects – Essential for building unique furniture pieces with angled or decorative edges, such as tables and shelving.

How to Choose the Best Mitre Saw

When choosing a mitre saw, it’s essential to consider key features to find the right tool for your projects, whether you’re tackling DIY tasks or professional carpentry. Here are the top specifications to keep in mind:

1. Blade Size

The most common blade sizes for mitre saws are 8-inch, 10-inch, and 12-inch. Larger blades allow for deeper and wider cuts, ideal for larger pieces of wood, while smaller blades are easier to control for intricate work.

2. Sliding vs. Non-Sliding Mitre Saws

Sliding Mitre Saws: These allow for more extended cuts, making them ideal for larger boards and wider materials.

Non-Sliding Mitre Saws: Compact and generally more affordable, these are great for precise cuts on smaller materials like trim and moulding.

3. Single vs. Dual-Bevel Mitre Saws

Single-Bevel Saws: These tilt in one direction (usually left), suitable for simpler angled cuts, and are ideal for tasks like framing or crown moulding.

Dual-Bevel Saws: Tilt in both directions, making it easier to make bevel cuts without having to reposition the workpiece, perfect for complex angles and detailed work.

4. Cutting Capacity

Consider the maximum cutting capacity of the saw, especially if you’ll be working with wider or thicker materials. Some mitre saws offer greater vertical cutting depth, which can be crucial for larger, denser materials.

5. Laser Guide or LED Light

A laser guide or LED light helps align cuts accurately, which is particularly useful for detailed, precision work. While not essential, these features can make setup and cutting more efficient.

6. Dust Collection System

Many mitre saws come with built-in dust collection ports that can be connected to a vacuum to reduce mess. A good dust collection system not only keeps your workspace clean but also improves visibility for safer cuts.

7. Portability and Build Quality

For those moving between job sites, a lighter, compact saw can make a big difference. However, if stationary, a more substantial build can offer added stability and reduced vibrations, enhancing accuracy.

8. Motor Power

Higher motor power (measured in amps) means more efficient cutting, especially for hardwoods or thicker materials. Look for a mitre saw with at least 10-15 amps for robust performance.

What Types of Blades Can Mitre Saws Use?

Mitre saw blades are available in a range of sizes, typically from 216mm to 350mm, ensuring compatibility with various mitre saw models. When choosing a blade, consider the kerf size. A narrow kerf requires less power to cut through materials and is ideal for precision cuts, while a wider kerf is designed for faster, more robust cuts, suitable for heavy-duty tasks.

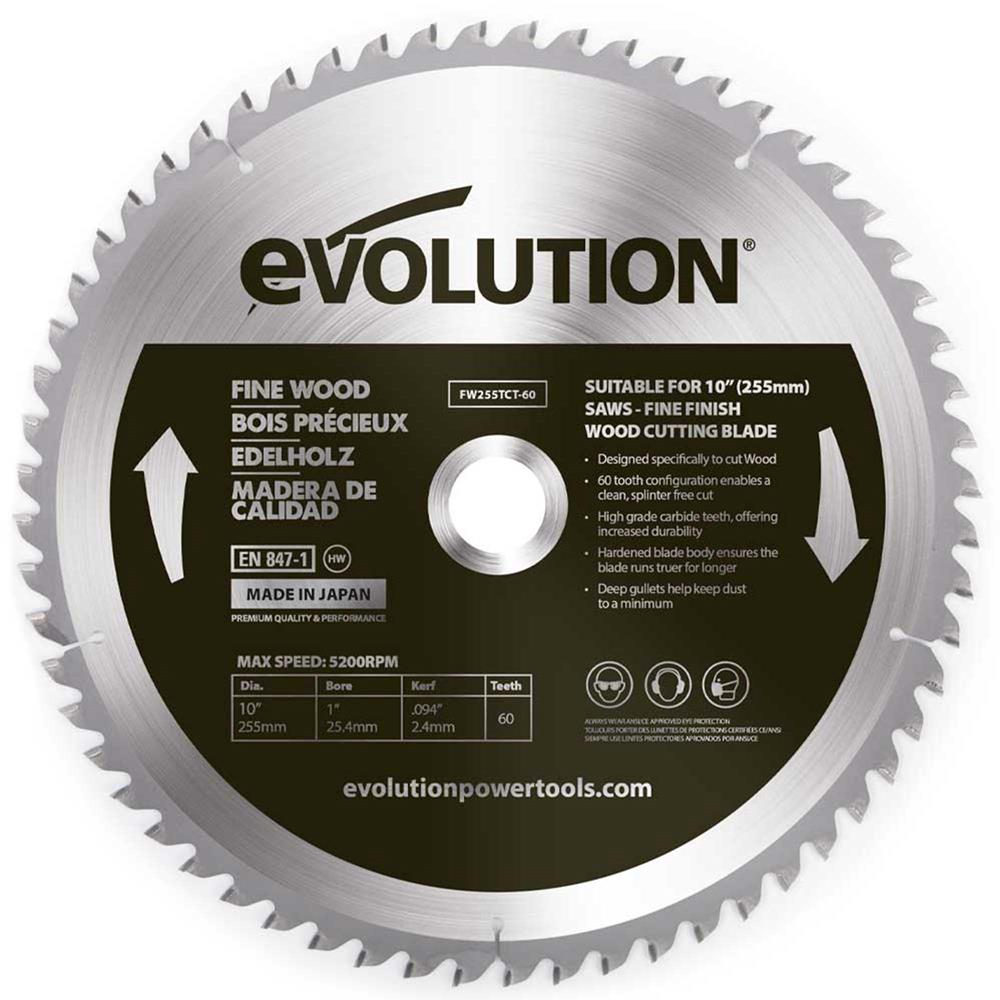

| Blade Type | Primary Application | Example Image |

|---|---|---|

| Carbide-Tipped Blade | Ideal for smooth, precise cuts in wood and plywood |  |

| Metal-Cutting Blade | Best for cutting through steel, aluminium, and other metals |  |

| Masonry Blade | Perfect for cutting concrete, brick, and other hard materials |  |

| Fine-Finish Blade | Used for fine cuts on furniture-grade wood or trim |  |

Popular Accessories for Mitre Saws

Choosing the right accessories for your mitre saw can significantly enhance its performance and make your projects easier to manage. From achieving precise cuts to maintaining a clean workspace, these accessories are designed to optimise your tool's functionality.

1. Saw Stands

A sturdy saw stand provides stability and support, especially when cutting larger materials. It also raises the saw to a comfortable working height, making it easier to handle lengthy workpieces and achieve precise cuts.

2. Dust Bags and Extractors

Dust bags and extractors are essential for keeping your workspace clean. They help capture sawdust directly from the cutting area, improving visibility and reducing airborne dust, which is especially beneficial when working indoors.

3. Clamp Sets

Clamps secure your materials firmly in place, allowing for safer, more accurate cuts. This accessory is particularly useful for repetitive cuts or when working with smaller, more intricate pieces that require stability.

Frequently Asked Questions

What types of cuts can a mitre saw perform?

Mitre saws are versatile tools primarily used for crosscuts, mitre cuts, and bevel cuts. Some models also perform compound cuts, which are a combination of a mitre and bevel cut, ideal for cutting crown moulding and complex angles.

What blade size should I use with my mitre saw?

Common blade sizes for mitre saws range from 216mm (8.5 inches) to 305mm (12 inches). The size you choose depends on the thickness and width of the materials you’ll be cutting. Larger blades are generally suited for bigger, thicker cuts.

Can I cut metal with a mitre saw?

Yes, but you need a specialised metal-cutting blade. Standard mitre saw blades are designed for wood and may struggle with metal. When using a mitre saw for metal, ensure it has a lower RPM and use appropriate safety precautions.

How do I maintain my mitre saw for optimal performance?

Regularly clean the sawdust and debris from your mitre saw, lubricate moving parts, and check the blade alignment. Additionally, sharpen or replace blades as needed and ensure the saw is stored in a dry environment to prevent rust.

What safety features should I look for in a mitre saw?

Safety features like blade guards, electric brakes, and dust extraction options are important. Blade guards protect against accidental contact, while electric brakes stop the blade quickly after the trigger is released, reducing the risk of injury.