At ITS we often get asked what exactly is an SDS Drill and whether or not its worth having in the tool box. In this article we hope to give you as much information as possible, so you can make the decision to add one to your arsenal or not!

What does SDS+ mean?

There are various claims for the meaning of SDS+, the most commonly accepted being ‘Slotted Drive System’ although it is more likely to stem from the original German phrase ‘steck, dreh, sitzt’ that translates as ‘insert, twist, fits’. Bosch use another term; Special Direct System, for international purposes.

How does an SDS+ work?

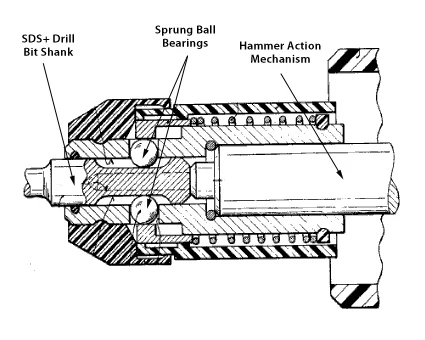

The ‘Slotted Drive System’ means that SDS+ drill bits have slots at the end of the shank which fit into the chuck of an SDS+ drill.

These slots or indentations allow the bit to be thrust forward by the hammer action of the drill, whilst still being retained by the drill due to 2 sprung ball bearings that lie in the slots of the drill bit. This differs from the standard drill chuck system where three arms grip the round drill bit.

Image below shows a diagram of an SDS+ chuck highlighting the key areas.

Image below shows a comparison between the SDS+ shank (Left) and standard (Right).

The hammer action on an SDS+ drill is driven by a piston firing the drill bit forward and pulling it back. The slots on the SDS+ drill bits allow an amount of back and forth motion and this, along with the smooth ball bearings, increases the strength of the hammer action of the drill. It also reduces friction inside the drill. In other hammer drills (or percussion drills) the whole chuck will move back and forth. As you can imagine this is a much less efficient way of delivering the energy, as the impact will be less concentrated than with an SDS+ drill.

All of this also means there is no need to lean in hard on to the drill to get it to work efficiently. The hammer action is sufficient without the need to apply a large amount of pressure so you are able to let the drill do the work.

What are the different types of SDS+ drill?

SDS+ drills come in 3 main types – 2 mode, 3 mode and 3 mode with changeable chuck.

| 2 mode | 3 mode | 3 mode with inter-changeable chuck |

|---|---|---|

| 2 mode drills have a rotary action and a rotary with a hammer action. This allows for drilling into wood and metal with the rotary only mode and also has a rotary with hammer action which rotates as well as the bit moving back and forth. | 3 mode drills have the rotary, rotary hammer and hammer only action. Using the chiselling function, this allows the drill to be used for more applications such as light breaking and removing tiles. | The 3 mode drills with a changeable chuck have the rotary, rotary hammer and hammer only action. The difference with these drills is that it allows the chuck to be changed quickly from an SDS+ chuck to one that accepts standard drill bits. |

What are the 3 modes of an SDS+ drill?

1. Rotary

Most drill users will be familiar with this mode where the chuck rotates the drill bit and the bit bites into the material. To be used only on soft or light materials. You can use standard drill bits in this mode with an SDS+ drill chuck adaptor.

2. Rotary with Hammer

This is as above; however, the piston inside the drill will drive forward, in turn driving the drill bit forward. This is the most common mode used when using an SDS+ drill as it achieves the desired goal.

3. Hammer Only

This is also known as ‘rotary stop’ or ‘chisel’ mode. The rotary motion of the drill is switched off and the hammer action only is applied. The piston inside moves back and forth driving the drill bit (usually a chisel or point SDS+ bit) back and forth, driving it in turn into the material.

Which SDS+ drill should I choose?

First you need to work out the application(s) for which you will need the drill. If you are regularly drilling into brick or other hard substances then an SDS+ drill is essential, if only for the time and energy saved.

You then need to decide if you also require the rotation stop function for chiselling action.

As a rule, 3 mode drills have always been a more expensive option; however, nowadays the price difference is often negligible on most models. The prices of all SDS+ drills are also much closer to a rotary or percussion drill price, which is another reason why more and more people are choosing to use an SDS+ drill.

Can I use normal drill bits in my SDS+ drill?

SDS+ drills work on the basic platform that all rotary drills work on which means the rotary motion can be utilised with a standard drill bit. You will, however, need to use a chuck adaptor to enable the drill bits to fit. Some SDS+ drills now come with interchangeable chucks so that you can use normal or SDS+ bits easily.

Example of a Changeable Chuck

Remember:

When using standard drill bits in a chuck adaptor or alternate chuck on your SDS+ drill, the hammer action must not be enabled.

I’ve heard SDS used with the word MAX – What is an SDS MAX Drill?

There are also SDS max drills and bits; these are for larger applications and both bits and drills are much larger than their SDS+ counterparts. They use a different system and the fitting on SDS max is not compatible with SDS+.

What accessories are available for SDS+ DrillS?

Many people are unaware of the sheer number of accessories and drill bits that are available to be used with an SDS+ drill. As well as standard SDS+ drill bits, ITS also stock extra-long bits and accessories such as the Armeg Channelling Chisels which produce quick, clean and smart channels in brickwork for trunking.

There are also specialist chisel bits available including SDS+ Scutch Comb Chisels for preparing a surface and Cable Guide Drill Bits to make guiding cables through walls painless.

Time saving essentials such as the Armeg Electrical Box Sinker, which allows you to drill a square hole in less than 2 minutes, can only be achievable with an SDS+ system. By drilling square holes into brickwork, without the need of using a hammer and chisel, electrical boxes can be installed very quickly and you can be guaranteed a perfect finish every time.